Nylon Blanking Plug (PG Series/Metric Series)

Protect your electrical installations with Nylon Blanking Plugs – the reliable solution for sealing unused cable entry points. Lightweight yet durable, these plugs offer superior insulation and corrosion resistance. Easy to install and versatile for various applications, they ensure safety and performance in any environment.

Additional information

| PG Series | Nylon Blanking Plug |

|---|---|

| Metric Series | Nylon Blanking Plug |

Available Standard Sizes

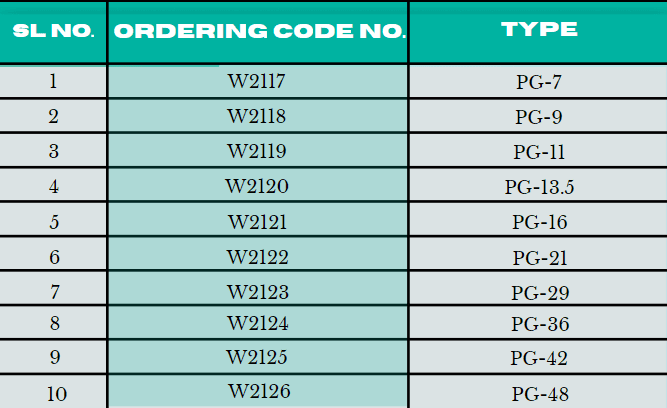

PG Series

Available Standard Sizes

Metric Series

Technical Description

Nylon blanking plugs offer a reliable solution for sealing unused cable entry points, ensuring safety, durability, and performance across various applications. With superior insulation properties, corrosion resistance, and easy installation features, these plugs provide a cost-effective solution for maintaining the integrity of electrical enclosures and equipment.

MSME Approved

IP-68 Protection

Export Quality

Made In India

30+ Years of Trust

KEY FEATURES

- Superior Insulation: Provides excellent electrical insulation, safeguarding against hazards and short circuits.

- Corrosion Resistance: Resists corrosion, chemicals, and environmental factors for prolonged durability.

- Quick Installation: Tapered design enables swift insertion and removal, saving time and effort.

- Versatility: Available in various sizes and configurations to meet different cable diameters and application needs.

- Cost-Effective: Offers a budget-friendly solution for sealing unused cable entry points, minimizing damage and contamination risks.

Material

- Crafted from high-quality Nylon, renowned for its durability, lightweight nature, and resistance to corrosion and chemicals.

- Nylon blanking plugs provide excellent insulation properties, making them ideal for a diverse range of electrical and mechanical applications.

Ingression Protection

- Engineered to safeguard against dust, debris, and moisture ingress, maintaining optimal performance in challenging settings.

- Tight fit and sealing mechanism prevent the infiltration of contaminants, preserving the integrity of enclosures and equipment.

Design Features:

- Precision-molded components guarantee a secure and dependable fit in cable entry points and openings.

- Tapered design facilitates effortless insertion and removal, streamlining the installation process.

- Available in multiple sizes and configurations to accommodate varying cable diameters and specific application needs.

Applications

- Ideal for sealing unused cable entry points in electrical enclosures, junction boxes, control panels, and equipment housings.

- Widely employed in automotive, marine, aerospace, and industrial contexts for dust and moisture protection.

- Suitable for both indoor and outdoor installations, offering versatility and reliability across diverse environments.

Advantages

- Excellent Insulation: Provides superior electrical insulation, mitigating the risk of electrical hazards and short circuits.

- Corrosion Resistance: Resistant to corrosion, chemicals, and environmental factors, ensuring prolonged durability.

- Quick Installation: Tapered design enables swift insertion and removal, minimizing installation time and effort.

- Versatile: Available in various sizes and configurations to cater to different cable diameters and application requirements.

- Cost-Effective: Offers a cost-effective solution for sealing unused cable entry points, reducing the likelihood of damage and contamination.

Quality Assurance

- Manufactured under stringent quality control standards to uphold consistent performance and reliability.

- Rigorously tested to comply with industry standards and regulations, guaranteeing safety and dependability.

- Endures extensive mechanical, environmental, and electrical testing to ensure enduring durability and performance.

Environmental Considerations:

- Environmentally friendly and recyclable, contributing to sustainability initiatives.

- Engineered for longevity, minimizing the need for frequent replacements and reducing waste.

- Low maintenance requirements promote energy and resource efficiency over time.