Nylon Reducers (PG Series/Metric Series)

Elevate your piping systems with our PVC Reducers – the ultimate solution for seamless transitions between different pipe sizes. Crafted from high-quality PVC, these reducers offer unparalleled durability, chemical resistance, and ease of installation. Whether you’re upgrading your plumbing, irrigation, or HVAC systems, our PVC reducers ensure efficient fluid transfer and long-term performance. Say goodbye to costly maintenance and hello to reliable, cost-effective solutions with our PVC Reducers.

Additional information

| PG Series | PVC Reducers |

|---|---|

| Metric Series | PVC Reducers |

Available Standard Sizes

PG Series

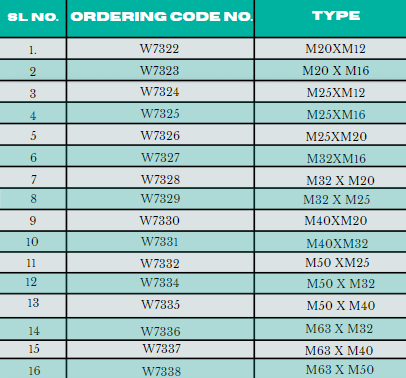

Available Standard Sizes

Metric Series

Technical Description

PVC Reducers stand as the epitome of reliability, versatility, and efficiency in piping solutions. With their robust construction, impeccable design features, and environmental considerations, they surpass industry standards and exceed customer expectations. Choose our PVC Reducers for your next project and experience seamless transitions, enhanced performance, and peace of mind like never before.

MSME Approved

IP-68 Protection

Export Quality

Made In India

30+ Years of Trust

KEY FEATURES

- Superior durability and resistance to corrosion, chemicals, and UV radiation.

- Tight sealing mechanism prevents ingress of dust, moisture, and contaminants.

- Precision-engineered with tapered ends for seamless connection between different pipe sizes.

- Available in various configurations to accommodate different flow requirements.

- Smooth inner surfaces minimize flow resistance and turbulence, ensuring efficient fluid transfer.

- Suitable for reducing the diameter of pipes in plumbing, irrigation, and HVAC systems.

- Versatile usage in wastewater treatment plants, chemical processing facilities, and industrial applications.

- Cost-effective solution for pipe size transitions, reducing installation and maintenance expenses.

- Lightweight and easy to install, reducing labor costs and effort.

- Certified compliance with industry standards and regulations, backed by warranties and technical support.

Material

- Manufactured from high-quality PVC (Polyvinyl Chloride), renowned for its durability, flexibility, and resistance to corrosion and chemicals.

- PVC reducers offer excellent electrical insulation properties, making them suitable for various indoor and outdoor applications.

- The PVC material is lightweight yet robust, providing ease of handling and installation in diverse settings.

- Resistant to UV radiation, moisture, and abrasion, ensuring long-term performance in harsh environments.

- Available in different PVC grades to meet specific requirements for temperature resistance and chemical compatibility.

Ingression Protection

- Engineered with a tight sealing mechanism to prevent ingress of dust, moisture, and other contaminants.

- Designed to meet IP65 or higher ratings, providing reliable protection against water and solid particles.

- Features gaskets or O-rings for enhanced sealing and resistance to environmental elements.

- Resistant to corrosion, rust, and degradation, ensuring continued performance in challenging conditions.

- Suitable for outdoor installations where exposure to water, humidity, and dust is common.

Design Features:

- Precision-engineered with tapered ends for seamless connection between different pipe sizes.

- Available in various configurations, including straight reducers, concentric reducers, and eccentric reducers, to accommodate different flow requirements.

- Features smooth inner surfaces to minimize flow resistance and turbulence, ensuring efficient fluid transfer.

- Incorporates flanged ends or threaded connections for easy installation and secure joint connections.

- Designed with chamfered edges to facilitate smooth transitions and reduce pressure drop in piping systems.

Applications

- Ideal for reducing the diameter of pipes and conduits in plumbing, irrigation, and HVAC systems.

- Widely used in wastewater treatment plants, chemical processing facilities, and industrial applications for fluid control and regulation.

- Suitable for connecting pipes of different sizes in residential, commercial, and industrial plumbing systems.

- Used in swimming pools, aquariums, and water treatment facilities for water circulation and filtration.

- Commonly employed in construction projects, landscaping, and agricultural applications for drainage and irrigation purposes.

Advantages

- Excellent Chemical Resistance: PVC material resists corrosion from acids, alkalis, and other chemicals, ensuring long-term durability.

- High Temperature Resistance: Suitable for use in environments with elevated temperatures, maintaining structural integrity and performance.

- Cost-Effective: PVC reducers offer a cost-effective solution for pipe size transitions, reducing installation and maintenance expenses.

- Lightweight and Easy to Install: PVC material is lightweight, facilitating transportation and installation, reducing labor costs and effort.

- Versatile: Available in various sizes, configurations, and colors to meet specific project requirements and preferences.

Quality Assurance

- Manufactured under strict quality control measures to ensure compliance with industry standards and regulations.

- Subjected to rigorous testing for dimensional accuracy, pressure resistance, and chemical compatibility, guaranteeing reliable performance.

- Thoroughly inspected for defects, imperfections, and surface irregularities to maintain product quality and consistency.

- Certified by regulatory authorities and independent testing laboratories for compliance with safety and performance standards.

- Backed by manufacturer warranties and technical support to provide peace of mind to customers

Environmental Considerations:

- PVC material is recyclable and can be repurposed for other applications, reducing environmental impact and promoting sustainability.

- PVC reducers require minimal maintenance and cleaning, conserving water and resources over their lifespan.

- PVC material does not corrode or degrade in soil or water, making it suitable for underground and submerged applications.

- PVC manufacturing processes adhere to environmental regulations, minimizing emissions and waste generation.

- PVC reducers contribute to water conservation efforts by enabling efficient fluid flow and distribution in plumbing and irrigation systems.